Articles

The DMAIC Cycle

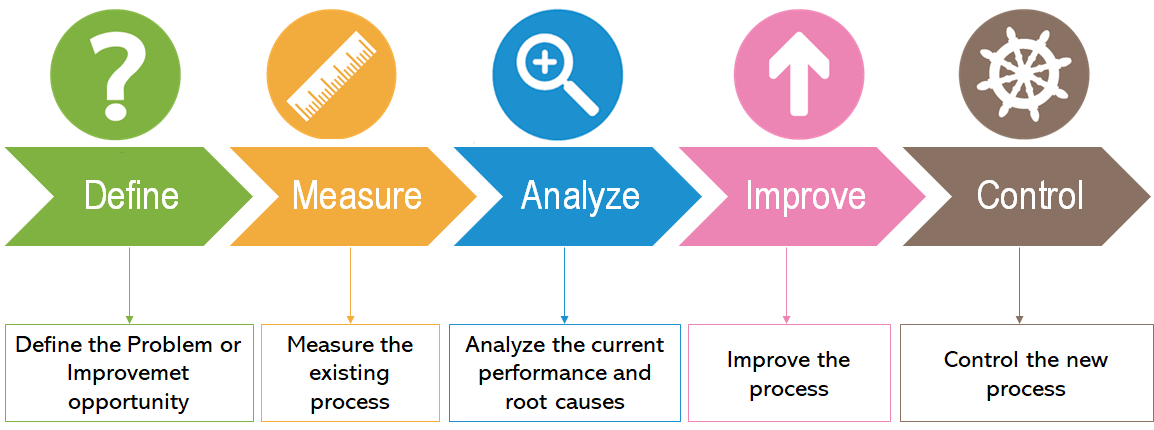

The DMAIC cycle is a data-driven problem solving methodology used to define, measure, analyze, improve and control processes to achieve continuous improvement and efficiency.

In today’s highly competitive business landscape, organizations are constantly looking for ways to improve their operations, reduce costs and improve customer satisfaction. One methodology that has proven to be effective in achieving these goals is Lean Six Sigma. At the heart of Lean Six Sigma is the DMAIC (Define, Measure, Analyze, Improve, and Control) framework, a structured problem-solving approach that enables companies to identify and eliminate inefficiencies. In this article, we’ll dive into this tool and explore its importance and use in operational excellence.

Defining the Challenge

The DMAIC methodology begins with the “Define” phase, which involves clearly articulating the problem statement and defining the goals of the project. This initial step requires a comprehensive understanding of the customer’s needs and expectations, as well as the identification of critical process areas that require improvement. By precisely defining the problem, organizations can ensure that subsequent efforts are aligned with desired outcomes.

Measuring for Success

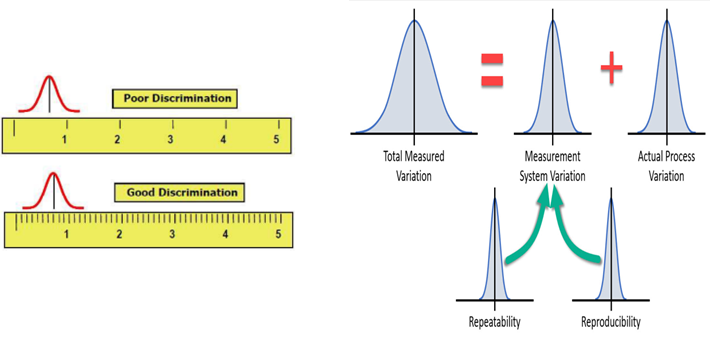

Once the problem is defined, the next step is to gather the relevant data and measure the performance of the existing process. This “measuring” phase involves collecting data using various tools and techniques. The goal is to gain insights into the current state of the process and identify areas for improvement. Accurate measurement provides a baseline against which future improvements can be evaluated.

Analyzing the Root Cause

With the data in hand, it’s time to move on to the “Analyze” phase. Here, the focus is on identifying the root causes of the problems or inefficiencies discovered in the previous steps. This phase usually involves using statistical tools, cause-and-effect diagrams, and other analytical techniques to identify the underlying factors that contribute to process variations or defects. A complete analysis allows organizations to prioritize opportunities for improvement and create effective solutions.

Improving the Process

The “Improve” phase is where you start to get your “hands on”. Armed with the insights from previous steps, organizations can now implement changes to eliminate root causes and streamline the process. This phase usually involves brainstorming sessions, pilot testing, and implementing process redesigns or improvements. By continuously monitoring the impact of improvements, companies can ensure they are moving closer to their goals and delivering greater value to customers.

Controlling for Sustainability

The final phase, “Control”, is crucial to sustaining the gains achieved from improvement efforts. It involves establishing control mechanisms, documenting standard operating procedures and implementing monitoring systems to ensure that the process remains stable and consistent over time. Furthermore, this phase focuses on training and equipping employees with the necessary tools and skills to keep the process improving. Ongoing analysis and periodic reviews are essential to detect and promptly address any deviations.

Conclusion

The DMAIC framework serves as the backbone of Lean Six Sigma initiatives, enabling organizations to address complex challenges, improve the efficiency of their processes and improve customer satisfaction. By following the sequential five steps of DMAIC, companies can achieve remarkable results such as reduced defects and increased productivity efficiencies.

At Erising, we specialize in providing comprehensive Lean Six Sigma services, offering expertise and support in implementing the DMAIC methodology. Our team of highly qualified professionals is dedicated to driving operational excellence and helping organizations reach their full potential. Click the button below to find out how we can help you.

registe-se e receba todas as novidades

Erase waste fostering rise

Telefone

Localização

Gab. MEC 3.11 e 3.12, Av. Rovisco Pais 1, 1049-001 Lisboa

Efficiency Rising, Lda © 2021 All Rights Reserved

Design e Desenvolvimento por Bestsites.pt